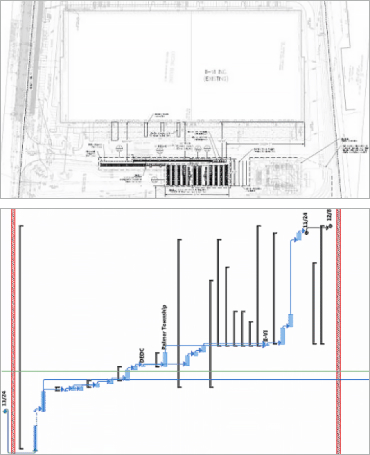

Substation Build for a Semiconductor Manufacturer

Data Center Strategy

Data Center Design and Engineering

Data Center Construction and Commissioning

Project Details

Sub-Station and Critical Power Fuel Cell

INTUVA was hired to design and build several substations and fuel cells to supply critical power for a semiconductor and specialty materials manufacturer in the Eastern US.

We were able to deliver critical power ahead of schedule, and managed to stay on budget, despite supply challenge delays.

Situation

Design & build new sub-station and fuel cells for critical power at 2 manufacturing plants

Need experienced peer review of both substation and Bloom Energy fuel cell systems

Problems coordinating engineers, suppliers' consultants & in-house resources

Design mistakes would cause permit and construction delays and added cost

Missing design & construction milestones lead to cost overruns

Resolution

Assigned dedicated Owner’s Rep team including Project Engineer, Project Manager & Assistant Project Manager

Value-engineered the design to improve permit likelihood and improve operability

Project delivery on-target and on-budget despite labor and supply challenges

Outcome

Utility company is fast-tracking utility approvals saving ~4 weeks on the schedule

This semiconductor and specialty materials manufacturer has multiple projects across multiple states

Scheduled to deliver critical power~2 weeks ahead of schedule

Highlights

Owner’s Representation Services

Engineering Peer Review Services

Delivered Ahead of Schedule

Stayed On Budget